- 產品型號 : IRB 360 FlexPickerTM

- 產品名稱 : 食品包裝 / 取、放機器人

Assembly

Material handling

Picking

Packing

- High speed flexibility

- High capacity – up to 3 kg payload

- Hygienic design for wash down applications

- Superior tracking performance

Integrated vision software

The IRB 360 FlexPicker™, is the SECOND GENERATION

delta robot solution for precision pick and place applications.

The robot has outstanding motion performance with shortest

cycle times at high accuracy, and high payload. The PickMaster

software is developed for ease of use and simplifies the

robot integration.

The IRB 360 range comprises four variants. The compact variant, IRB 360-1/800, has a 800 mm diameter work area and its small footprint saves floor space and makes it easy to fit into compact packaging machines.

The IRB 360-1/1130 (standard version) has a working range optimized for the fastest picking applications. It now also comes in a high payload variant, IRB 360-3/1130 that can speed up the throughput by taking more products at a time or for simply handling heavier products. The standard version has been complemented with a version with longer arms targeted at the solar, food and beverage industries. It has a working range of 1600 mm which will enable the robot to reach over large conveyors and machines.

The IRB 360 is designed to work in meat and dairy applications.

A stainless option with all metal parts in stainless is

IP69K validated so that it can be washed down with industrial

detergents and high pressure hot water. The robot does not

only have great corrosion protection but is also designed with

smooth and rinse-off surfaces and lubricant free joints

Setting up an application becomes easy using the PickMaster

software. Based on experiences from 10 years, PickMaster

has evolved into an invaluable help for integrators and users

of IRB 360. It simplifies the vision configuration and offers the

application tools needed for an efficient high speed picking

application.

The reliable, market leading IRC5 controller is also an integral

part of the FlexPicker™ robot solution. The IRC5 with True-

Move™ and QuickMove™ ensures the highest speed together

with path following facilities - enabling the robot to track fast

moving conveyor belts with high accuracy. The IRC5 is also

available in a panel-mounted version that offers substantial

space savings and easy integration into machines and production

lines.

Specification

| Robot versions | Handling capacity | Diameter | No. Axes |

| IRB 360-1/800 | 1 kg | 800 mm | 4 |

IRB 360-1/1130 |

1 kg |

1130 mm |

3/4 |

| IRB 360-3/1130 | 3 kg | 1130 mm | 3/4 |

| IRB 360-1/1600 | 1 kg | 1600 mm | 4 |

| Supplementary load | |||

| on upper arm | 350 gram | ||

| on lower arm | 350 gram | ||

| Integrated signal supply | 12 poles 50V, 250mA | ||

| Integrated vacuum supply | Max. 7 bar/max vacuum 0.75 bar |

Physical

| Robot mounting | Inverted |

| Weight | 120-145 kg |

Performance

| Position repeatibility | 0.1 mm |

| Angular repeatability | |

| Standard and stainless axis 4 | 0.4° |

| Wash-down axis 4 | 1.5° |

| Cycle time* | |

| Typical cycle time for ∅1130 mm standard variants |

| Cycle | Payload kg | Cycle time s |

| 25/305/25 | 0.1 | 0.30 |

| 25/305/25 | 1 | 0.36 |

| 25/305/25 | 3 | 0.54 |

| 90/400/90 | 0.1 | 0.44 |

| 90/400/90 | 1 | 0.51 |

| 90/400/90 | 3 | 0.70 |

The cycle times in the table are measured under real conditions but cycle

times may vary depending on the actual application (tool data, path radius,

gripper activation etc.)

* Cycle times for IRB 360-1/800 and IRB 360-1/1600 differ in cycle time.

Please use RobotStudio or real cycle time tests to verify actual cycle time.

| Conveyor tracking** | |

| Constant conveyor | Conveyor speed |

| speed [mm/s] | Repeatability [mm] |

| 200 | 1.0 |

| 350-750 | 1.5 |

| 800-1400 | 5.0 |

| Start/stop conveyor [mm/s] | Repeatability [mm] |

| 500 (start/stop in 0.2 sec) | 3.5 |

** The tracking performance is measured under real conditions with IRB 360-1/1130 and PickMaster. The figures may vary depending on the actual robot max. speed and acceleration performance in relation to what the application demands.

Electrical Connections

| Supply voltage | 200-600 V, 60 Hz |

| Rated power | |

| Transformer rating | 7.2 kVA |

| Power consumption at max load | |

| Type of Movement | IRB 360/1 |

| Typical pick - and - place | 0.477 kW |

| cycle with 1 kg payload |

Electrical Connections

| Supply voltage | 200–600 V, 50/60 Hz |

| Rated power Transformer rating | 4.5 kVA |

| Power consumption typicly | 0,4 kW |

Environment

The base box and the arm system can be ordered independent of each other in standard, wash-down or stainless design. Depending on the combination the robot fulfils protection classes IP 56, IP 67 or IP 69K. If wash-down or stainless axis 4 is choosen, the robot can be washed down accordding to industrial standard.| Ambient temperature IRB 360 manipulator |

±0°C to +45°C |

| Relative humidity | Max. 95 % |

| Noise level | < 70 dB(A) |

| Safety | Double circuits with supervision, emergency stops and safety functions, 3-position enabling device |

| Emission | EMC/EMI shielded |

| Options axis 4 | Stainless wash-down Clean Room, class 5/7 (certified by IPA) Stainless Clean Room class 5/7 (certified by IPA) Collision detection |

| Data and dimensions may be changed without notice | |

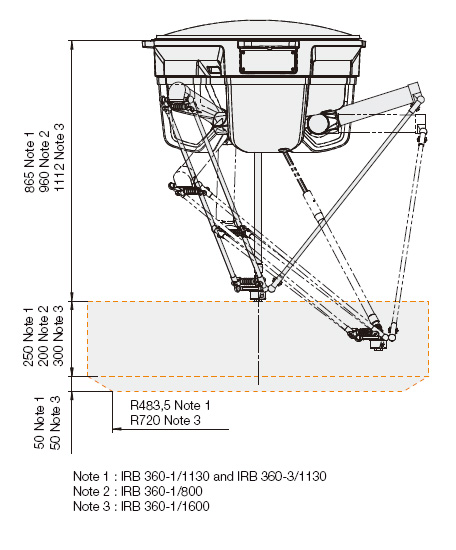

Working range and physical dimensions