- 產品型號 : IRB 6640/ IRB 6640ID

- 產品名稱 : 點焊機構 / 物料搬運機器人

Material handling

Machine tending

Spot welding

IRB 6640 –

a stronger robot – the next generation

The IRB 6640 is a new generation of large robots, replacing

the highly successful IRB 6600.

It’s based on proven components used for IRB 6600, which

ensures easier maintenance and exchangeability as well as a

high up time.

IRB 6640 comes in different arm lengths and matching handling

capacities.

IRB 6640ID, Internal Dressing, has its process cables routed

inside the upper arm. The cables follow every motion of the

robot arm instead of coming into swing in irregular patterns.

The IRB 6640 is adaptive for various applications

Upper arm extenders and different wrist modules allow customization

to each process. As the robot can bend fully backwards,

the working range is greatly extended and the robot

fits well into dense production lines. Typical application areas

are material handling, machine tending and spot welding.

The robot is also available with different options for different

working environments, such as Foundry Plus, Foundry Prime

and Clean Room.

Higher payload - lower weight

One of the strongest benefits of IRB 6640 is the increased

handling capacity. For the IRB 6640ID, the payload is increased

from 185 to 200 kg, which meets the requirements

from the heaviest spot welding applications.

The maximum payload is 235 kg, which makes the robot

suitable for many heavy material handling applications. The

robot also follows the tradition of having outstanding inertia

capabilities, which makes it possible to handle not only heavy

but also wide parts. Collision resistance is also a great feature

ABB robots are well known for.

Easy maintenance and installation

There are several new features in the area of service, such as

simplified fork lift pockets and more space in the robot foot,

which gives easy maintenance. In order to simplify installation,

the weight has been reduced by almost 400 kg.

Increased path performance

IRB 6640 runs the second generation of TrueMove™

and QuickMove™. This gives the robot more accurate motions,

which, in the end, means less time for programming as

well as a better process result. This software also supervises

internal robot loads, which means reduced risk of overload

and longer robot lifetime.

Passive Safety Features

Passive Safety Features include load identification, movable

mechanical stops, EPS (Electronic Positions Switches) and a

stiff steel structure.

IRB 6640ID – Internal dressing in the upper arm

This version has the process cabling for spot welding routed

inside the upper arm. This gives a controlled motion with different

benefits, such as predictable dress pack lifetime, longer

dress pack lifetime and less spare part cost; a more compact

robot when dressed and also a reliable simulation of dress

pack motion.

Focusing on high production capacity, compact design, simple service and low maintenance cost, IRB 6640 is the perfect robot for various applications!

Specification

Robot versions |

Reach |

Handling |

Center |

Wrist torque |

6640-180 |

2.55 m |

180 kg |

300 mm |

961 Nm |

6640-235 |

2.55 m | 235 kg | 300 mm | 1324 Nm |

6640-205 |

2.75 m |

205 kg |

300 mm |

1264 Nm |

6640-185 |

2.8 m |

185 kg |

300 mm |

1206 Nm |

6640-130 |

3.2 m |

130 kg |

300 mm |

1037 Nm |

6640ID-200 |

2.55 m |

200 kg |

300 mm |

1262 Nm |

6640ID-170 |

2.75 m |

170 kg |

300 mm |

1190 Nm |

| Extra loads can be mounted on all variants. 50 kg on upper arm (except ID) and 250 kg on frame of axis 1. |

||||

| Number of axes: | 6 | |||

| Protection | Complete robot IP 67 | |||

| Mounting: | Floor mounted |

Performance

| Positions repeatability | 0.07 mm |

| Path repeatability | 0.7 mm |

| Axis movements | Working range 6640 | Working range 6640ID | Axis max speed 6640 |

| Axis 1 Rotation | +170° to - 170° | +170° to - 170° | 100 - 110°/s |

| Axis 2 Arm | +85° to - 65° | +85° to - 65° | 90°/s |

| Axis 3 Arm | +70° to - 180° | +70° to - 180° | 90°/s |

| Axis 4 Wrist | +300° to - 300° | +300° to - 300°* | 170 - 190°/s |

| Axis 5 Bend | +120° to - 120° | +100° to - 100° | 120 - 140°/s |

| Axis 6 Turn | +360° to - 360° | +300° to - 300° | 190 - 235°/s |

* For IRB 6640ID axis 4 and 6 together max +300° to -300°

A supervision function prevents overheating in applications with intensive and frequent movements.

Electrical Connections

| Supply voltage | 200-600 V,50/60 Hz |

| Power consumption | ISO-Cube 2.7kW |

Physical

| Dimensions robot base | 1107 x 720 mm |

| Weight | 1310 - 1405 kg |

Environment

| Ambient temperature for mechanical unit | |

| During operation | + 5° C (41°F) -+50°C (122°F) * |

| During transportation and | - 25° C (13°F) -+55°C (131°F) |

| storage for short periods | storage for short periods |

| (max 24h) | |

| Relative humidity | Max 95 % |

| Max 95 % | Noise level |

| Safety | Double circuits with supervision, emergency stops and safety functions, 3-position enable device |

| Emission | EMC/EMI-shielded |

| Options | Foundry Plus Foundry Prime Clean Room, class 5 (certified By IPA) |

| * In a high-speed press tending application, max ambient temperature is 40 °C. | |

Data and dimensions may be changed without notice

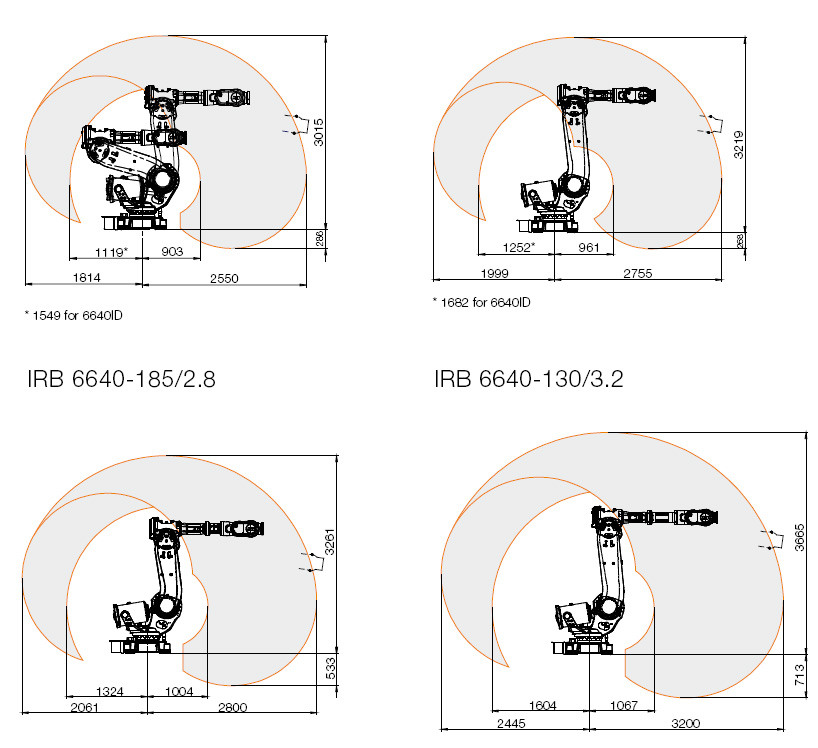

Working range

IRB 6640-180/2.55,

IRB 6640-235/2.55,

IRB 6640ID-200/2.55

IRB 6640-205/2.75,

IRB 6640ID-170/2.75